Crate Handling & Packing

Connecting all operations in the processing plant

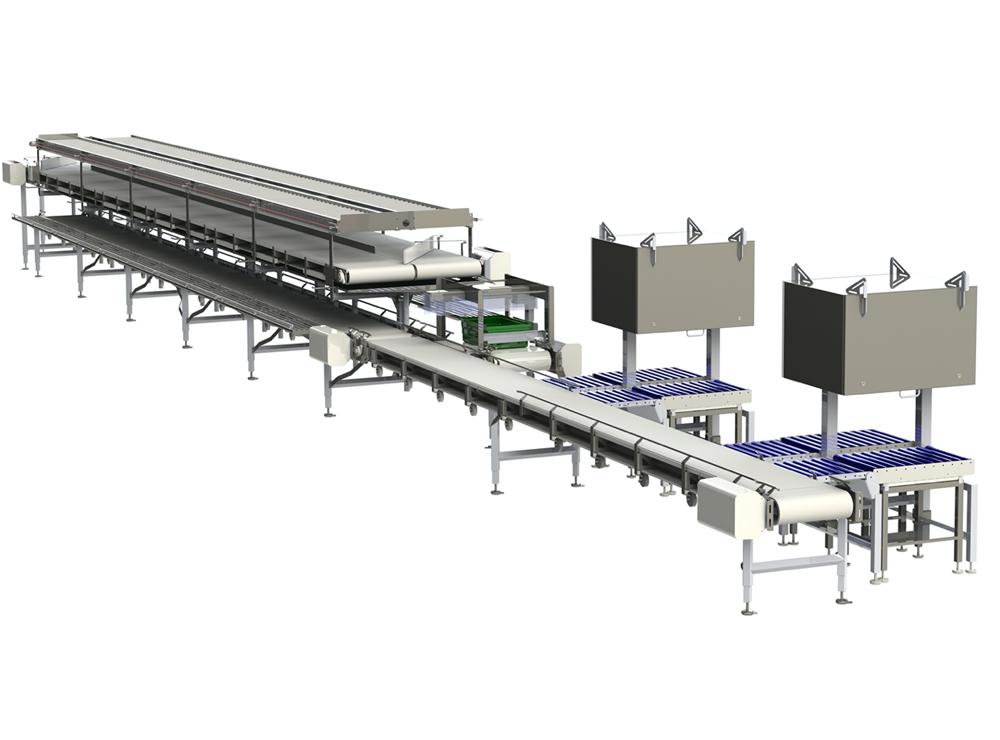

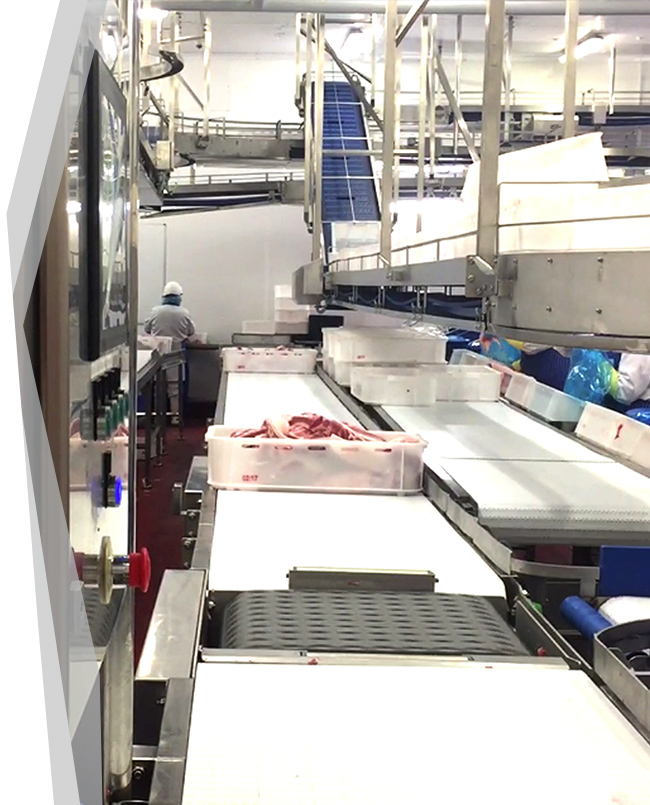

Complete Solutions For Your Crate Handling Needs

We can integrate our handling & packing solutions in your existing customer production management system, or offer completely new solutions including full destination control.

Full destination control of internal crates is crucial and we can offer complete solutions designed for each individual customer.

The system consists of horizontal and or vertical modular conveyor belts for crate transport.

Identification of each crate and its contents is key, therefore the crate handling system can use RFID (Radio Frequency Identification) or barcodes as identification on each crate to make sure there is full control of the production line.

The crate handling system is controlled by a PLC HMI control system, which provides realtime equipment status which can be fed back to a central control room.

Systems can be configured to include a range of options, including an integrated crate washing and drying system.

Handling systems are specific to a customer’s precise needs and factory layout.

Handling & Packing Solutions To Increase Production Efficiency

SF Engineering offers a range of handling & packing solutions, all customized to the specific requirements of each individual production facility.

With a focus on the ergonomics for the operator, we offer customised packing systems for packing products into carton or plastic trays for end of line packing.

Our packing solutions increase process efficiency and ensure optimum product flow.

They are available in various configurations and meet stringent hygiene standards.

The optimal design of the overall solution enables process times to be minimised while maintaining maximum output, contributing to low operating costs and an optimised line footprint.

Built to suit your site requirements

These are examples of some of the handling & packing solutions that we manufacture.

If you can’t find what you need, please contact us today to discuss your handling & packing requirements.

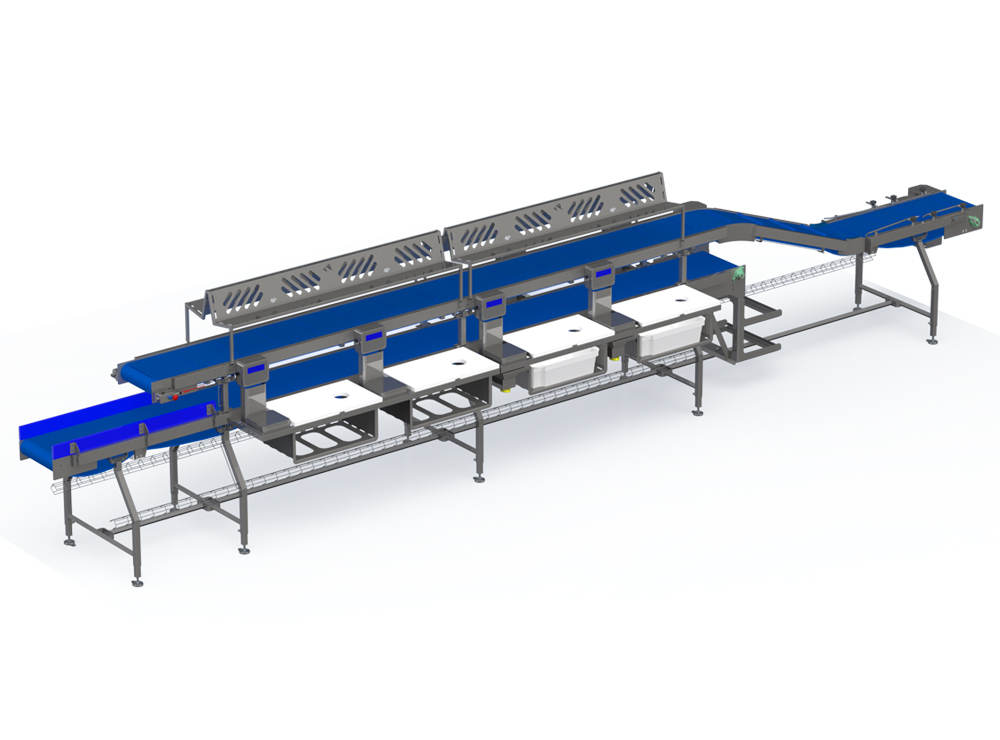

Carousel Packing

More Information on Carousel Packing

The SF carousel packing station can be custom designed to suit your site and packing requirements. These efficient packing systems are ergonomically designed to assist the packer. Whilst the easy-clean, sturdy design saves valuable labour time during the cleaning process.

For further optimisation of your end of line process, the packing line can be modified to feed OCM stations.

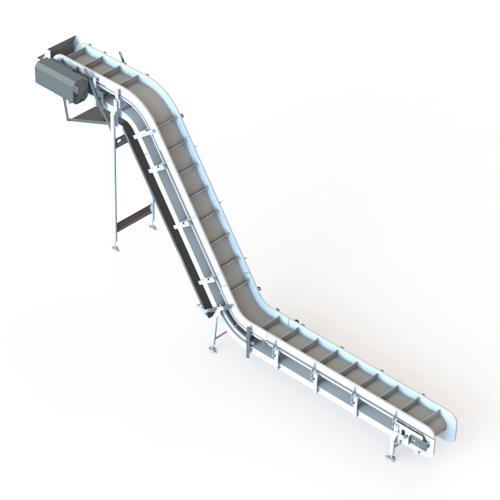

Packing Stations

More Information on Packing Stations

SF packing stations are designed to ergonomically assist packers to pack food products into cases in an efficient manner.

The number of packing stations, infeed and outfeed systems can be configured to suit your packing requirements.

All of our packing stations are designed for use within a hygienic food production area where reliability and ease of cleaning is a necessity.

The conveyors are designed using components that have been proven to last in a 24/7 production environment.

Pace Packing

More Information on the SF Pace Packing Line

The SF Pace Packing Line is an ergonomic solution for dressing and packing numerous added-value meat and poultry products into retail trays that have been fed from a multihead weigher or a fresh food weigher.

The product is delivered between flights on the product conveyor while the second lane is used to carry retail trays.

The tray and product travel along the conveyor side by side and operators can carry out a pre-designated portion of the styling required.

Bulk Bagging

More Information on SF Bulk Bagging System

Capable of bagging 2.4 tonnes per hour, the Bulk Bagging System enables a single operator to pack 4 x 10kg bags per minute.

It is designed with 20kg load cells and an autostop infeed system that pauses just before the target weight is achieved. It is also IP65 rated and the modular belt helps to reduce clean down time and water usage.

Rotary Tables

More Information on the SF Rotary Table

The SF Rotary Table is designed to buffer packaged product to suit the packing requirements of a food production facility. The products are delivered to the table where they can rotate until a packing operative is available to pack the product into a box or crate.

Get in touch to ask a question about our handling and packing solutions

Our dedicated team is here to help and answer any questions you might have.

We will do our very best to get back to you as soon as possible.

Alternatively speak to our team of experts now

Other products you may be interested in

Multihead Weighers

Find out more >

Metal Detectors

Find out more >