Automated BBQ Kebab Skewering with One-Third Labour Savings and Triple the Throughput

Automated BBQ kebab skewering solutions from SF Engineering can cut the number of operators you need by a third while tripling throughput. The solution can be adapted to any skewering product or requirement and return on investment timescales are fast.

The example BBQ kebab skewering solution highlighted in this article was for a large food processor that produces chicken kebab skewers. One of its customers asked for a significant increase in capacity heading into BBQ season as a requirement to retain its supplier contract. The food processor has a long-standing relationship with SF Engineering and asked us to develop a solution.

The images used in this article are of the solution going through pre-delivery inspection processes at our manufacturing facility in County Sligo, Ireland.

Reducing Labour and Increasing Throughput

The manual versus automated figures in this example demonstrate the ROI and productivity potential of our automated BBQ kebab skewering solution:

- Operators reduced from 16 to 10 – more than one-third reduction in the number of operators required.

- Throughput increased from 60 skewers per minute to 200 skewers per minute – more than 3x increase in throughput.

With this solution, our customer will be able to produce three times the number of skewers with a third fewer staff.

Automated Kebab Skewering Process

The product is tipped into a hopper which feeds the product onto one of two flighted conveyors. The operators can control the speed of the conveyor to adjust to current conditions.

Operators place the product into the skewer moulds. The moulds were custom designed and manufactured to meet the requirements of our customer and the style of product.

The skewers are loaded into the auto feeder in bulk. A pneumatic cylinder then pushes the skewer through the meat loaded into the moulds.

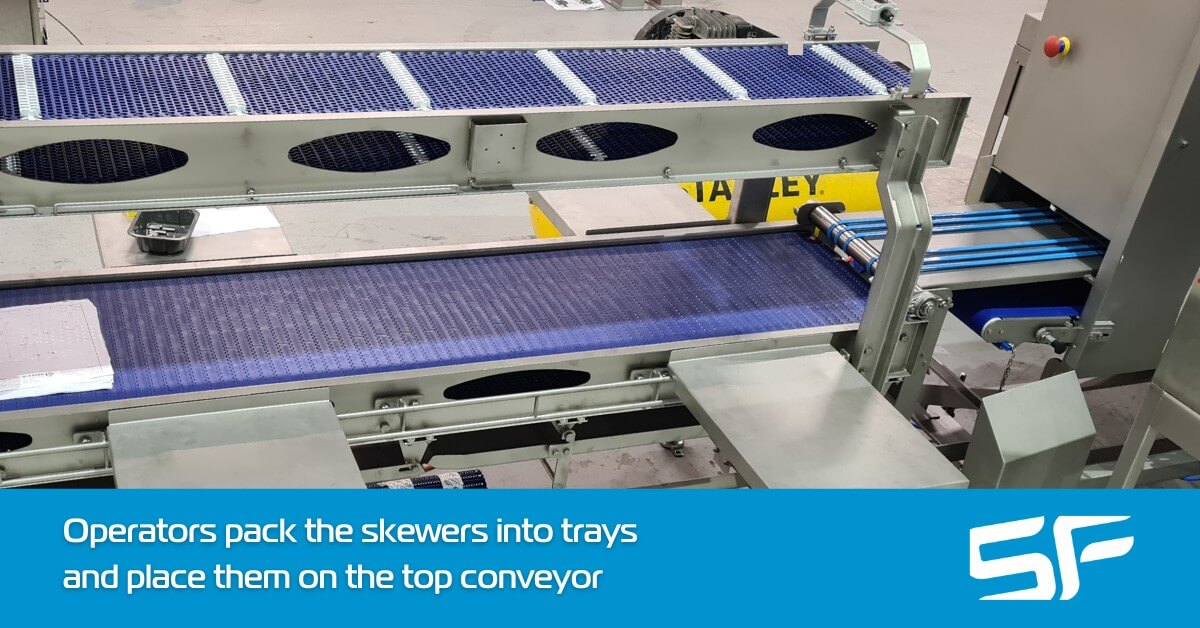

The kebab skewers come out of the automated skewering machine to a packing station. Operators pack the skewers into a tray before placing the tray on the top conveyor. This conveyor takes the trays to a checkweigher and then onto a tray sealer.

Automate Your Kebab Skewering Processes

To discuss your kebab skewering processes, the automation options that are available, and the throughput gains and labour savings that you can make, get in touch with us at SF Engineering today.