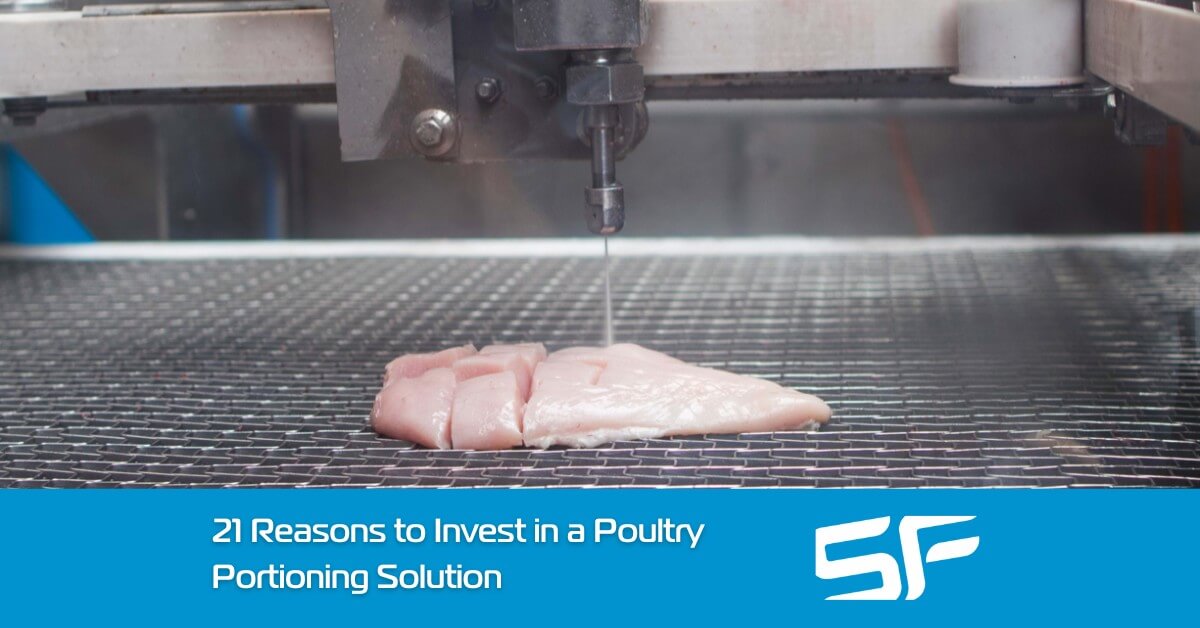

21 Reasons Why Now Is the Time to Invest in an Automated Poultry Portioning Solution

There are many ways poultry processing facilities can be improved and modernised with advanced technologies, updated processes, and optimised product flows. One area that can deliver fast returns on investment is portioning with the introduction of an automated poultry portioning solution. Below are 21 reasons why now is the right time to invest, including:

- Automation reasons to invest.

- Waterjet portioning technology reasons to invest (based on the Marelec PORTIO Jet).

- SF Engineering reasons to invest.

Automation Reasons to Invest

Whether you currently portion your poultry product manually or you have legacy equipment on your production line, the following points are compelling reasons why now is the time to invest in a modern automated portioning solution.

1. Optimise Yield

The best poultry portioning solutions can optimise yield at close to 100 percent. This results in less product being thrown away or classified as byproduct.

2. Reduction in Skilled Labour

Poultry portioning solutions require less labour than a manual portioning line, plus the skills levels required can also be significantly reduced.

3. Programmable Cutting Patterns

Modern poultry portioning solutions are digitally controlled with programmable cutting patterns, enabling you to cut cubes, strips, or steaks. The best solutions can even cut unusual shapes with high degrees of accuracy.

4. Consistent Performance

Consistency is a problem on manual portioning lines, as operator quality and speed of work can vary. With an automated portioning solution, you will get a consistent level of performance.

5. Improved Operator Safety

Manual portioning lines require operators to use knives, increasing safety risks. These risks can be significantly reduced and even eliminated with an automated portioning solution.

6. Fast Return on Investment

With optimised yield, a reduction in skilled labour, and consistent performance, you can expect a rapid return on your investment with a modern poultry portioning solution.

Marelec PORTIO Jet Reasons to Invest

The Marelec PORTIO Jet uses waterjet technology for cutting, alongside state-of-the-art laser scanning and programmable algorithms that manage the portioning process. The machine is capable of cutting product into specific shapes, fixed weights, or a combination of both.

Additional reasons for investing in the Marelec PORTIO Jet portion cutting solution include:

7. Highly Accurate Cutting

Using waterjets to portion your poultry product delivers more accurate cuts than cutting with a blade.

8. Reduced Product Waste

When poultry is portioned using a blade, small pieces of product end up on the blade. This doesn’t happen when waterjet technologies are used.

9. Reduced Contamination Risk

Blades can be damaged, with fragments of the blade potentially ending up contaminating your product. This risk is eliminated with waterjet technologies.

10. Hygienic and Easy to Clean

The Marelec PORTIO Jet has a hygienic design that is easy to clean.

11. Low Cost of Ownership

Compared to other automated poultry portioning equipment, the Marelec PORTIO Jet solution has a low cost of ownership. So, not only can you expect a rapid return on investment, but ongoing costs will also be low.

12. User Friendly Interface

The interface that your staff will use to operate the machine is easy to learn and intuitive to use.

13. Modular Design

The Marelec PORTIO Jet portioning machine has a modular design, so it can be adapted and scaled according to the needs of your business.

SF Engineering Reasons to Invest

At SF Engineering, we have extensive experience designing, manufacturing, installing, and supporting food production equipment and solutions for poultry processing facilities. As a result, there are additional reasons for investing in an automated portioning solution from us at SF Engineering:

14. Poultry Processing Expertise

We have extensive experience working with poultry processors, including many of the largest companies in the industry. That experience ranges from single machine installations up to full factory fitouts.

15. Integrated into Your Production Line

We offer a comprehensive service at SF Engineering that includes integrating your new portioning machine into your line for seamless operation and maximum control.

16. In-Feed and Out-Feed Solutions

We can also design and install in-feed and out-feed conveyors to optimise process automation and ensure you get maximum benefit from your investment.

17. Overall Factory Flow and Process Optimisation

We will also bring extensive factory flow and process optimisation knowledge and experience to your project. Where improvements can be made, we’ll identify and present them to you.

18. Additional Equipment Integration

We can also supply and integrate additional equipment to further enhance your poultry production line, including upstream or downstream quality control equipment, as well as packing stations, tray sealing solutions, and more.

19. Flexible Installation and Commissioning Processes

We understand that most poultry processing facilities operate to very tight timescales to ensure customer orders are properly fulfilled. As a result, we’ll plan the installation and commissioning of your new portioning equipment with the aim of causing as little disruption as possible. This includes installing overnight and/or at weekends as necessary.

20. Complete Support, Including Training

As experts in food processing equipment, we’ll provide a full end-to-end service that includes staff training and enhanced levels of support in the weeks after the new machine is installed.

21. Ongoing Servicing, Repair, and Spare Parts Support

We can also support your portioning machine and other equipment across its full lifecycle with high-quality servicing solutions and spare parts.

Speak to a Solutions Engineer

To speak to one of our solutions engineers about automating portioning processes in your poultry manufacturing facility, please contact us at SF Engineering today.