Taking Portioning Precision and Versatility to the Next Level with Waterjet Cutting Technologies

The cutting and portioning methods used on food production lines have a significant impact on the quality and integrity of the final product that reaches the consumer. Cutting and portioning methods also significantly impact the profitability of food manufacturing operations. One of the best portioning and cutting options available is waterjet cutting.

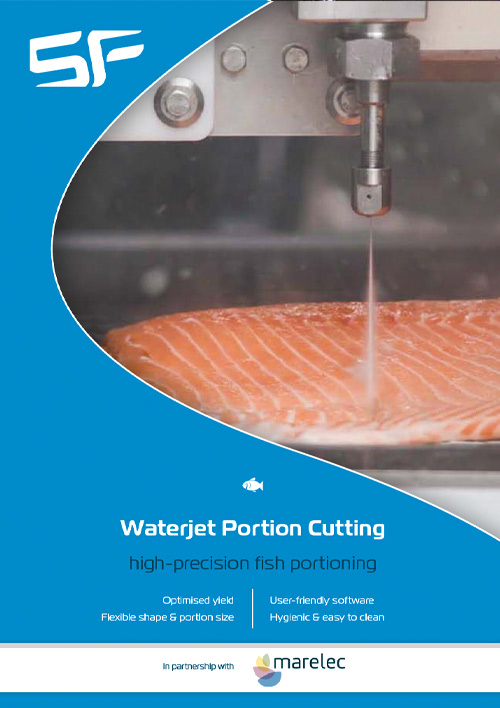

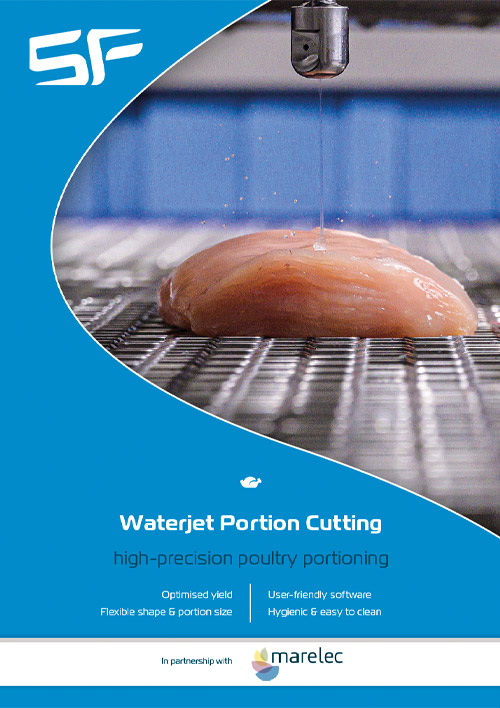

Instead of using a cutting blade to portion food products, waterjet cutting technologies use high-pressure, ultra-high-precision jets of water to make the required cuts.

At SF Engineering, we have waterjet portioning options for a range of food products, including poultry products, whitefish, and salmon.

The Benefits of Waterjet Portioning and Cutting Technologies

High Precision

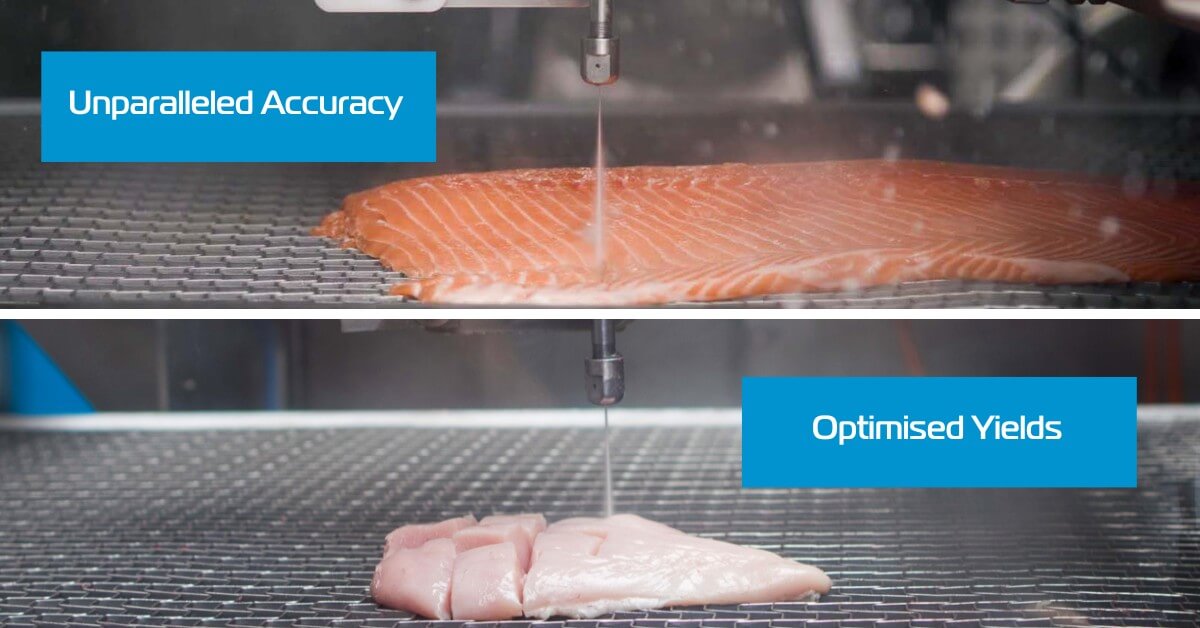

Waterjet portioning and cutting technologies deliver high-precision cuts to achieve exact shapes and portion sizes. This optimises yield and improves product and pack appearance.

Versatility

One of the main advantages of waterjet technologies over other cutting methods is the ability to cut random shapes. Whatever the shape or size of cut that is required, high levels of versatility can be achieved because of the way the cutting nozzles operate and the flexibility of the software.

Even intricate shapes with precise dimensions are possible, as well as angled and curved cuts.

Improved Hygiene

Waterjet technologies portion and cut food products without the need for a physical blade. As a result, there is nothing that comes into contact with the product to complete the cut. This improves hygiene as there is less equipment to clean.

Improved Food Safety

Food safety is also enhanced when you use waterjet portioning and cutting machines as they reduce the risk of cross-contamination of food products. Other contamination risks are also reduced or eliminated. For example, as there is no cutting blade, the risk of broken cutting blade fragments contaminating food products is eliminated.

The risk of bacteria transfer is also reduced with waterjet cutting technologies, further improving food safety.

Reduced Product Waste

Less food waste is produced when you use waterjet portioning technologies as the cutting kerf is minimised, especially when you compare waterjet cutting to other cutting technologies, including cutting with a blade. A minimised cutting kerf results in reduced product loss from the cutting process.

Cutting with a blade also results in material sticking to the blades. This doesn’t happen with waterjet technologies.

While we are talking about very small amounts of product, they add up, particularly on high throughput lines.

Improved Operator Safety

Advanced portioning solutions that use cutting blades include innovative features to protect operators from the dangers of the blade. However, there is always a risk of injury when a cutting blade exists. This risk is eliminated with waterjet cutting technologies.

Longer Shelf Life

With a reduced risk of contamination, food products portioned using water jet technologies can have a longer shelf life.

Improved Sustainability

Many of the points above lead to sustainability improvements in your food manufacturing operations. Improved operator safety creates better working conditions, for example, while reduced product waste enhances economic sustainability as your facility can become more profitable.

There are also environmental sustainability benefits, particularly on the most advanced waterjet cutting machines. Those environmental benefits include reduced water usage in the cleaning process because of hygienic machine designs, as well as solutions that recycle the water used in the cutting process, further reducing the volume of water that is required day-to-day.

Waterjet Portion Cutters from SF Engineering

At SF Engineering, we provide waterjet portioning machines from our equipment partner Marelec. Marelec is an industry leader in portioning equipment for the meat, poultry, and fish industries.

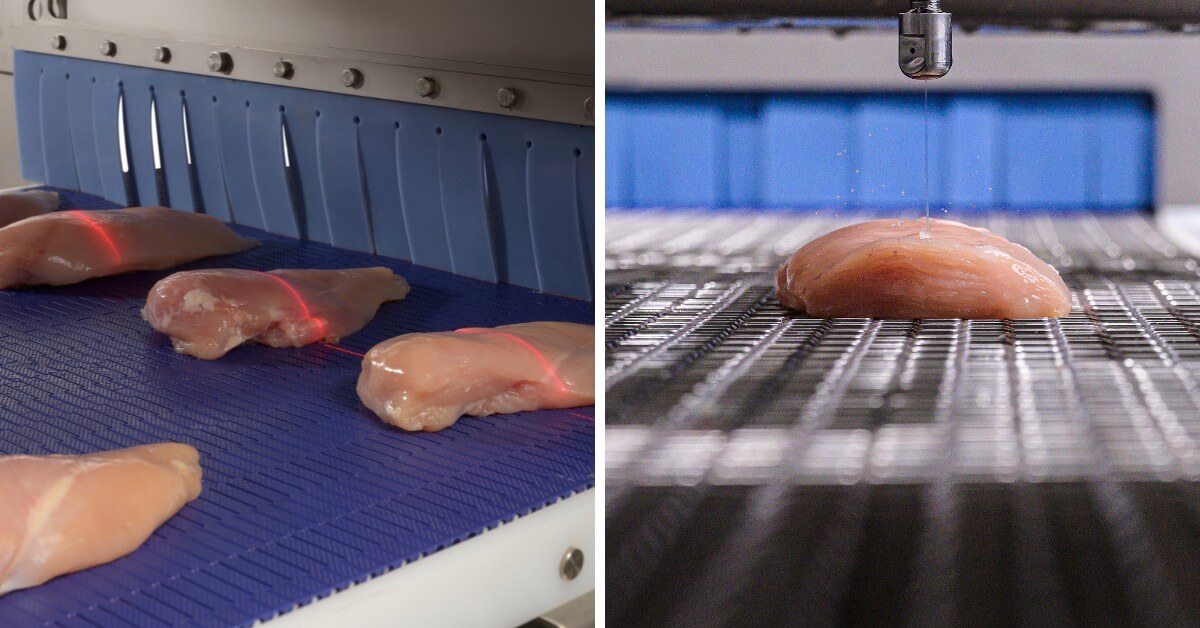

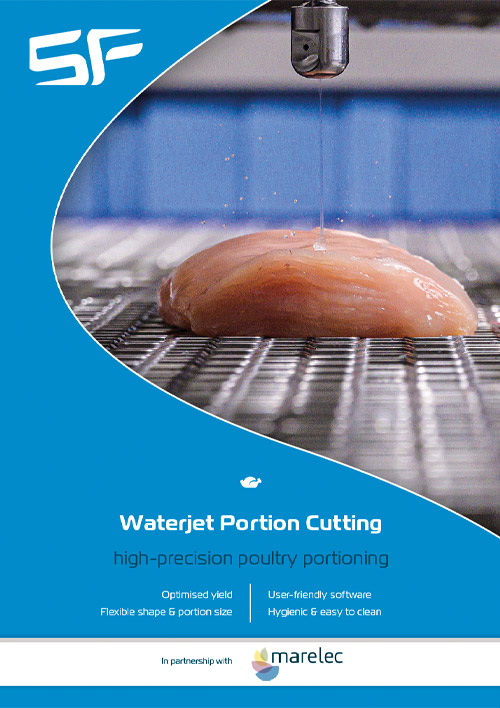

Poultry Portioning Using the Marelec PORTIO JET

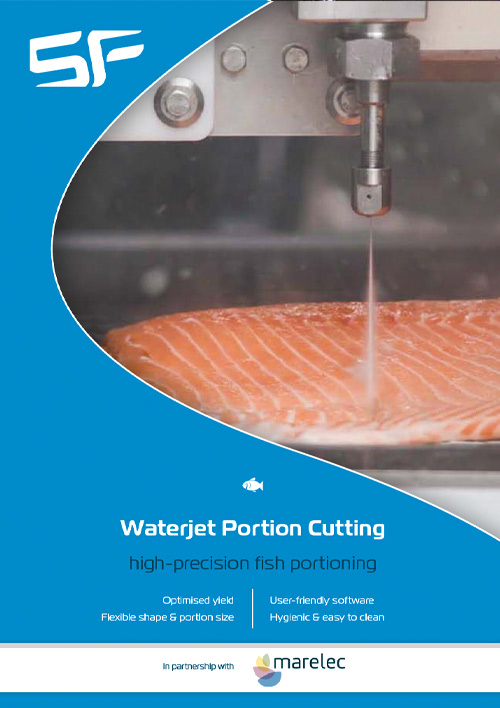

Fish Portioning Using the Marelec PORTIO JET

The Marelec PORTIO JET range includes advanced software that works with high-quality cameras and lasers to calculate precise cuts in real-time, delivering a cutting pattern that offers optimal results. The PORTIO JET also has a modular design that can be adapted to your requirements.

You will also benefit from SF Engineering’s expertise and support when you invest in a Marelec PORTIO JET. We can provide in-feed and out-feed systems, as well as upstream and downstream solutions for your production line. We also provide full ongoing support for the lifetime of the machine, including servicing, maintenance, and spare parts.

Download the latest brochure

Waterjet Poultry Portioning

Waterjet Fish Portioning

Waterjet Poultry Portioning