Portion Cutter Buying Guide for White Fish and Salmon Processors

Portion cutters for white fish and salmon products will improve the productivity of your manufacturing lines and the quality of product offered to your customers. Choosing the right portion cutter will also increase the profitability of your fish processing line. This portion cutter buying guide has been specifically tailored for white fish and salmon processors to help you choose the right machine.

Modern portion cutters create uniform fish portions typically based on thickness, weight, or a combination of thickness and weight. There are different options, however, so it’s important to make a choice based on the requirements of your line.

Our buying guide will give you an overview of the options and features that are available in advanced portion cutter solutions. However, we can also provide you with specific help and advice – contact a member of our team today to discuss your fish processing portion cutter requirements.

Objectives When Choosing a Portion Cutter on Your Fish Processing Line

By introducing a portion cutter to your fish processing line, or upgrading an existing portion cutter, there are four main objectives you should work to achieve:

- Deliver on customer presentation and quality requirements

- Increase the primary product ratio as much as possible

- Optimise the utilisation of raw material

- Maximise product yield

Questions to Ask Before Choosing a Portion Cutter

- What do your customers want?

- What are your competitors offering and how can you offer a better product?

- What is the quantity of product that you need to portion?

- What speed do you need the portion cutter to operate at to achieve your required line throughput rate?

- Will the portion cutter need to produce different cuts and/or cut different products?

- What shape or shapes do you need your product cut into?

- What sizes of product will be fed into the portion cutter? Larger fish products may require three cameras, for example, whereas one camera might suffice for smaller raw products.

- Do you need the portion cutter solution to also separate the head of the fish or trim the tail?

- How will you present the product in its final packaging?

Shape and Size

Advanced portion cutter solutions create fish portions that are a specific size, weight, or a combination of both. Examples include uniform portions like strips and dices, as well as portions that have a more natural fish appearance.

Portion cutters can be programmed to produce the weight and appearance that you want to achieve, but there are variations in capabilities. For example, to create fish portions that have a more natural appearance, the best option might be a portion cutter that can cut the product at an angle. The ability to control the angle of the cutting knife can also produce portions that have a larger plate coverage. However, not all portion cutters have the ability to cut at angles.

The best approach is to define at the outset of the process the type of products that you want the portion cutter to produce. This will then inform your buying decision.

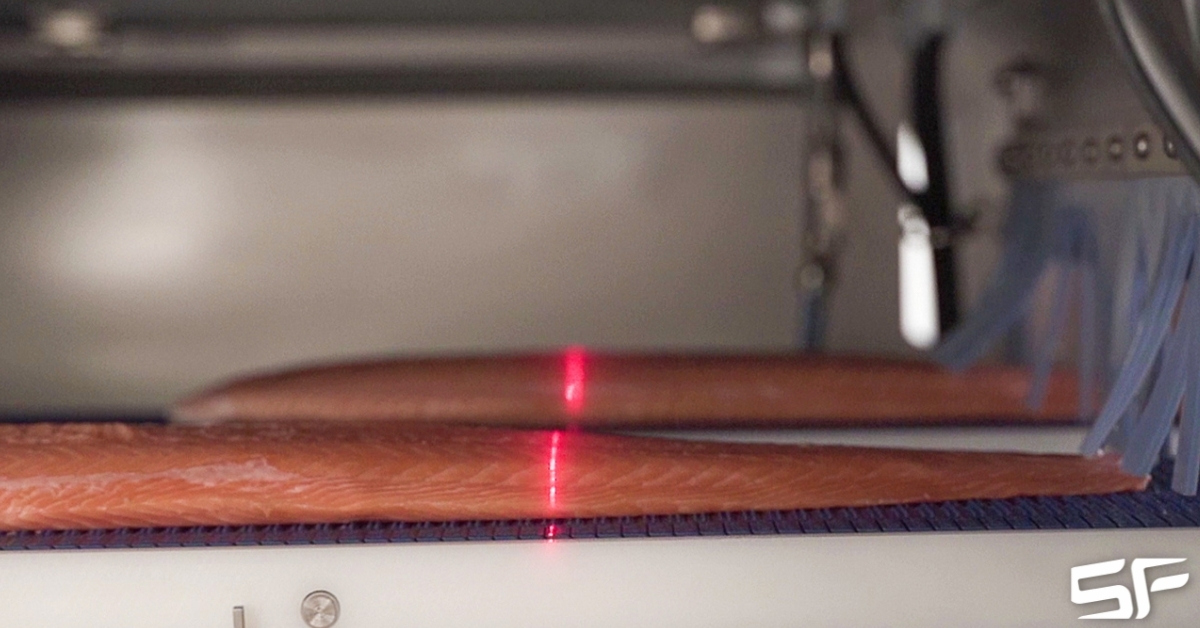

Portion Cutter Cameras

Camera capabilities are one of the main features of advanced portion cutter solutions. The cameras used in modern portion cutters are typically laser cameras. They are designed to scan the product to produce a 3D model that the software then uses when calculating the cut to achieve the target weight and thickness.

Laser cameras are used for this function as they deliver the highest levels of accuracy.

Lower-cost portion cutters may have one camera that scans the fish, usually from above, to create a 3D model of the product.

For larger and/or more rounded fish products, three-camera portion cutter solutions deliver better levels of accuracy. The cameras are positioned with one above the product and on each side.

The Importance of Portion Cutter Belts

The belt that feeds the fish product through the portion cutter is important not only for the portioning function, but also for the reliability of the machine and its overall cost of ownership.

The belt in the portion cutter you choose should be high-quality and specifically designed for fish products. In particular, the belt should be designed to prevent the fillets from moving during the portioning process.

In some situations, an additional product holder will be recommended to ensure the fillets remain in place on the belt.

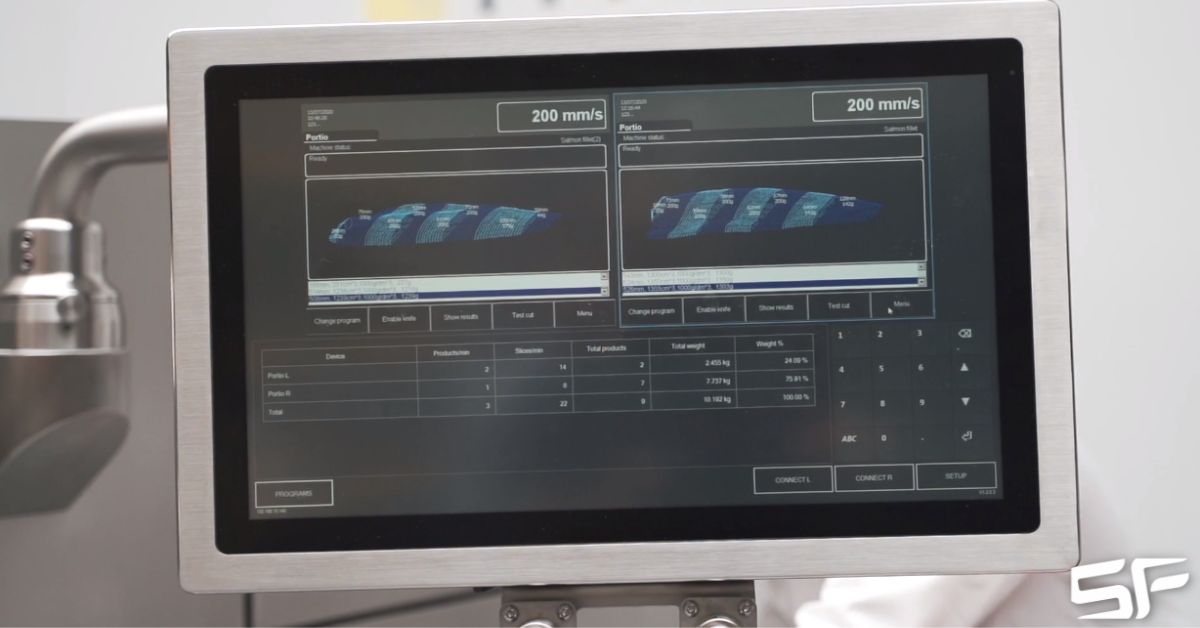

Portion Cutter Software

The software that comes with your portion cutter should be powerful enough to program the machine with your exact requirements, as well as to aid ongoing fine-tuning. However, it is also important the software is easy to use, with a learning curve that is as small as possible. This will enable your operators to retain control over as many processes as possible.

Hygiene and Cleaning

Cleaning routines should be engineered into the design of the portion cutter, enabling easy cleaning both inside and out.

Portion Cutter Footprint

Footprint is another important consideration, as portion cutters come in different shapes and sizes. In many fish processing facilities, minimising the footprint of all equipment is an important consideration. When it comes to portion cutters, you’ll need to get a balance between the machine’s footprint and its functionality, particularly in relation to throughput rates.

Expert Advice for Fish Processors on Portion Cutters and Other Equipment

At SF Engineering, we work with leading equipment partners to ensure you have access to the best fish processing solutions on the market. We also have decades of experience in the food processing industry as well as market-leading aftersales support. Get in touch with us today to discuss your fish portion cutting requirements.